Alexander Dennis ‘Next Generation’ buses on track

Having revealed the Enviro 400 EV and its little sister, the Enviro 100 EV, at Farnborough at the end of last year, Alexander Dennis gave people the chance to get behind the wheel of its next generation of electric buses, B&CB was there to get to grips with the buses and talk to the staff from Alexander Dennis that are behind their design and development

Over three days, operators, local authorities and the media were given a chance to drive and ride in the ‘Next Generation’ Alexander Dennis double- and single-deck electric buses at UTAC/Millbrook proving ground.

Welcoming the audience on the third day of the event, Chris Gall, Group Engineering Director at Alexander Dennis, said the key message to get across is that the vehicles have gone through validation and the manufacturer is now building on the test phase.

The Enviro400EV went through its VCA and type approval testing towards the end of last year. The Enviro100EV is now coming towards the end of its testing, being three-months behind its sister model in terms of the testing phase. Chris said it still requires fine tuning until it is fully certified.

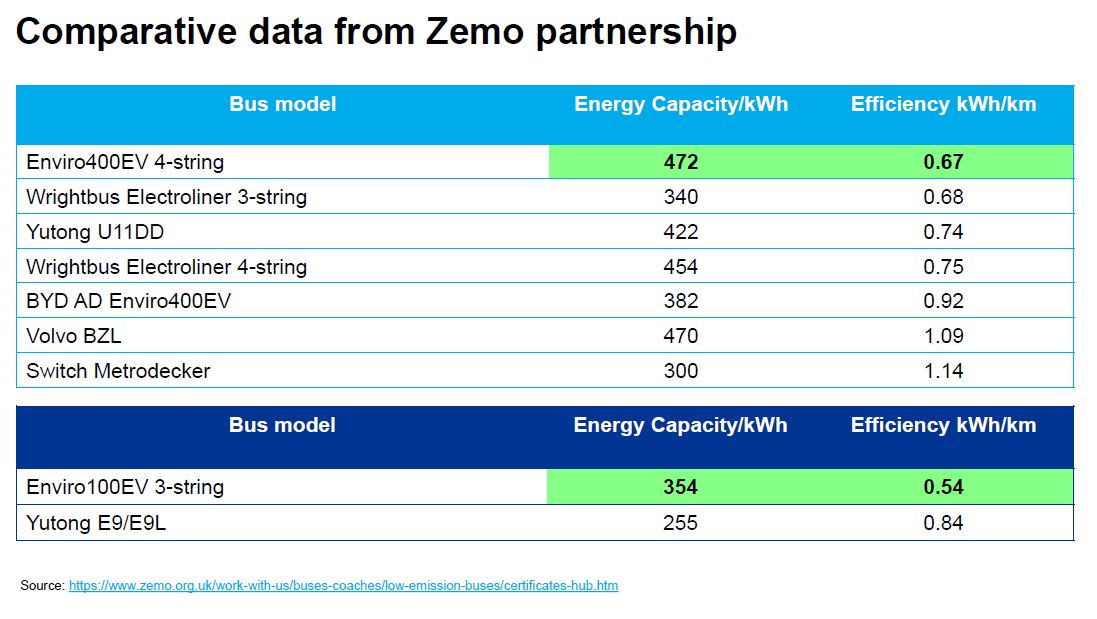

The buses have both been designed, engineered and tested in the UK, Chris emphasised. They have both achieved leading results in terms of their green credentials, the Enviro400 becoming the most efficient battery-electric double-decker tested to Zemo Partnership standards to date. Tested at UTAC Millbrook, the double-decker was recorded to have an average energy consumption of 0.67kWh/km across the UK Bus Cycle. This shows the vehicle delivers a 10% efficiency advantage over competitors’ vehicles of comparable battery size.

Alexander Dennis is now calibrating its computer modelling to reflect the real-world performance of the vehicles in UTAC FEMFET testing, but says that the modelled performance has come remarkably close to the figures achieved on the track in a standardised, simulated duty cycle. Discrepancies were relatively small.

The UK Bus Cycle represents a mix of common operating conditions with separate phases modelled on inner urban, outer urban and rural routes. Alexander Dennis puts part of its performance down to its use of the heavy-duty version of the Voith Electrical Drive System.

Combined with the Enviro400EV’s NMC battery system, supplied by Impact Clean Power Technology, this allows 88% of its 472kWh capacity to be used. The 0.67kWh/km energy consumption in the UK Bus Cycle gives the electric double-decker a theoretical operating range of up to 620km (385 miles) on a single charge.

The Enviro100EV looks set to achieve 0.54kWh/km across the UK Bus Cycle. “It provides outstanding efficiency, outstanding range in a small package,” said Chris Gall, but he emphasised that, as with all test cycles, the figures are a gauge and not the real-world consumption figures, which will vary enormously depending on route, ambient temperature and many other factors. In operation, Alexander Dennis expects the 400EV to achieve around 1.14kWh/km.

Maintaining style elements of its forebears, both the single- and double-decker have a front end designed to meet the 2024 London safety standards, such as the windscreen being contoured to deflect the impact in the event of a collision with a pedestrian. Chris said the glass achieved good scores on TRL’s impact testing.

Chris is proud of the warrantable energy throughput – the total energy that a manufacturer expects its battery to deliver throughout its lifetime. Alexander Dennis has worked with its battery supply partner Impact Clean Power Technology to increase the warrantable energy throughput to 1.6GWh over eight years for the Enviro400EV with 472kWh battery, or 1.2GWh with 354kWh battery. On the Enviro100EV, an energy throughput of 1.2GWh can be warranted when the bus is fitted with the larger 354kWh battery system, or 800,000kWh for the 236kWh battery option.

Chris described these numbers as the best figures in the industry for this area, saying the batteries should last longer than any other product currently on the market.

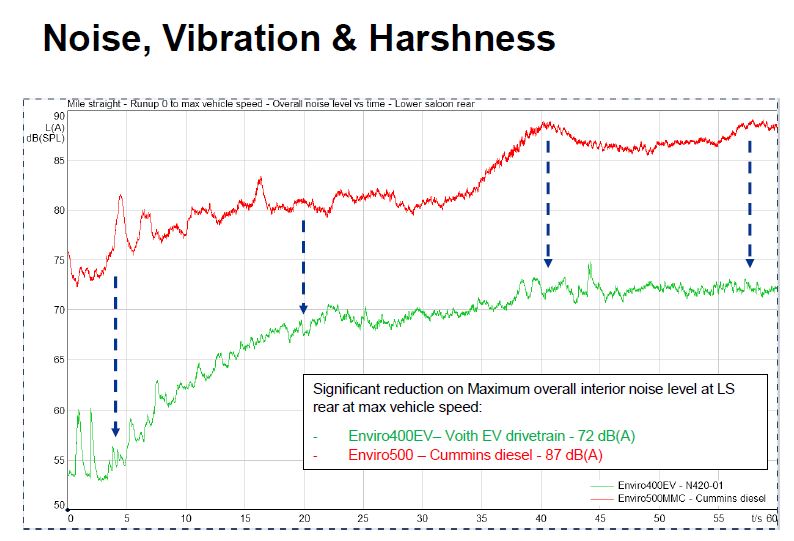

Extensive testing has gone into saloon noise and vibration on the vehicles, something Chris described as a passion of his. The vehicle achieved a 15dB reduction in noise compared to the comparative diesel and which equates to a 50% real-world reduction in noise. Chris said: “They are a pleasant place to be. It’s about getting the passengers on buses and keeping them happy.”

Attention has also been focused on the HVAC system, supplied by Grayson, with Chris noting ‘significant improvements in performance’ – perhaps twice as fast to heat the saloon as the previous model engineered with BYD. The HVAC and battery heating can take place before the buses go into service each day through the battery charging cycle.

In a system independent of the battery, the HVAC can be programmed through the charger, bus or remotely to pre-heat the interior and get the batteries to optimal temperature ready for the driver to take the first duty.

On the track

‘Next Generation’ Enviro400EV

After the introduction to the day and the vehicles, it was time for the group of operators and other attendees the chance to see the vehicles in the metal. After an initial drive around a traffic cone-marked course on an area of hardstanding by an official Alexander Dennis driver, attendees were given a chance to get behind the wheel to sample the handling. The mini-course featured hard bends, swerves and a straight section.

Getting comfortable in the driver’s seat, one of the first things to notice is the positioning of the Camera Monitoring System (CMS) screens. Alexander Dennis accepted criticism that they are not ideally sited and is already working on repositioning them optimally.

As the bus ably climbed a slope, Paul Davies, President and MD at Alexander Dennis, said: “It has that big motor for higher-speed topographical work.” As with all electric buses, energy is recovered on downhill runs.

He added: “We are at almost at 300 miles a day with battery power. We said 265 miles on the Enviro400EV, but we think that’s conservative.” He believes it is offering similar performance to an equivalent hydrogen double-decker, but at less cost and less complexity.

‘Next Generation’ Enviro100EV

After the Enviro400EV, it was time to sample the Enviro100EV. Boarding the bus, it is apparent the vehicle has been given the ‘big bus feel’ but in a smaller package, the door-forward configuration playing its part in that. Seating has been designed intelligently, with seats placed into the forming over the wheelarch, facing sideways.

The battery packs are placed mainly under the floor, with some batteries on the roof. Steel frames compose the sides and the roof is made of a composite. Chris Gall explained the bus has been through an ‘extensive weight optimisation exercise’. It was a success, he claimed, achieving an unladen weight of 9.5tonnes, better than the manufacturer’s target.

Taking the bus around the traffic cone course, the vehicle is lively and agile; a joy to drive. The front overhang has been kept to a minimum by using 17.5-inch wheels, and will be a boon for reducing corner damage on tight urban routes or narrow country roads. The driver’s cockpit from Continental is almost identical to that of the Enviro400EV – a deliberate design feature – with electrical handbrake and push-button drive selection.

The LCD screen which can be used to set the preferences for the way the bus performs is protected by a password, and the over-the-air functions have passed stringent EU cybersecurity compliance, which will encompass all telematics systems.

Enviro100EV has a top-speed of 62mph, while the Enviro400EV can reach 56mph, the Voith Electric Drive System (VEDS) selected being the medium-duty VEDS for the 100EV and the heavy-duty VEDS for the 400EV, with differing axle ratios. This was put to the test on Millbrook proving ground’s one-mile straight, where the ‘big little bus’ performed impressively. With its independent front suspension, handling was impressive, as was its turning circle and acceleration up hills.

As with all EBs, the new buses have hefty friction brakes although Chris says the regeneration does so much of the ‘heavy lifting’ of deceleration, the friction brakes could be hugely reduced in size: “The legislation hasn’t caught up with electric bus brakes yet,” he told Bus & Coach Buyer. “They have a lot of unnecessary unsprung weight.”

‘Bus delivers in the long term’ – Paul Davies, Managing Director

Talking to B&CB onboard the Enviro400EV as it made its way around the various stretches of test track at the proving ground, Paul Davies, President and MD at Alexander Dennis, told B&CB he is pleased with the interest the two new vehicles have gained so far.

“We have what we believe is a very compelling product,” he said, adding that the entire development cycle has taken just two years, though involving 220 AD staff and 80 contractors.

“These buses are built around the passengers – we put them into the design first,” but he said the emphasis for the operator on the vehicle is longevity. “We think the driveline will need only one battery change across a 20-year lifespan,” he said.

The longevity of the batteries is a core function. TfL defines end of life based on a daily duty of 150km, so in the batteries’ first life (they are upcycled to other duties when changed) they have to achieve this distance on each daily charge for as many years as possible.

Paul Davies added that if the government does eventually cease funding electric buses through ZEBRA, then the question of what the lease market looks like will also be asked. “Our buses are mandated for an 18-year service life,” he said. “Logically, because there is no diesel driveline, the buses should be put under less stress. I’m confident to say this bus could do two seven-year London contracts.”

The choice of Lithium Nickel Manganese Cobalt (NMC) batteries achieves the optimal energy density but Chris admits that the market is gradually ‘chasing out’ this battery chemistry as further advances are being made with existing and new battery chemistries. The buses can be compatible with any new battery chemistry.

Considering other electric buses on the market, Paul admits Alexander Dennis is not going to win on price, but with superior quality backed up by the business’ rich heritage building buses: “You have to be joined at the hip with operators,” he said.

“We can monitor the battery, right down to driver behaviour. That delivers value in the long term. We have our AD24 aftermarket service and that offers a long-term advantage. When I talk to operators, they tell me AD24 is so reliable and they know it’s going to be there for them.”

There are currently 150 Enviro400EVs sold, with Stagecoach and Transdev among the orders. And more are set to be announced. The Enviro100EV has already sold 50, with Stagecoach and Shuttle Buses putting their name down for the model.