ZF launches ‘brake by wire’ system

New motorised brakes reduce passive friction, extending electric vehicle range, and eliminate the need for brake fluid

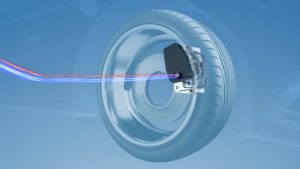

ZF has launched a new, purely electro-mechanical brake system which does away with hydraulic fluid.

The brake – aimed at the electric vehicle market – sees braking force generated at each wheel by an electric motor, without a hydraulic system and brake fluid. The brake system was co-developed at ZF’s centres in China, the USA, and Germany for the global car market.

“Our purely electrically controlled braking system is a significant addition to our portfolio of networked chassis systems,” said Dr. Holger Klein, CEO of ZF Group. “With such by-wire systems, we are opening the door to a new era of vehicle control.” Klein added that this is especially true in software-defined and electrically driven vehicles where this type of brake system has even more advantages and open up new freedom in design and development.

In a so-called ‘dry’ brake system, brake fluid is not required. Brake pressure is therefore no longer generated by the pressure of fluids in the hydraulic system, but by electric motors. Brake signals from the pedal to the electric motor are also transmitted purely electrically, which is why the term ‘dry brake-by-wire’ is used.

Compared with conventional braking systems, the new brake-by-wire system, like Integrated Brake Control (IBC), enables shorter braking distances, better recovery of braking energy, and lower maintenance costs. During automatic emergency braking, the braking distance at a speed of 100 km/h can be up to nine meters shorter than with conventional braking systems. In addition, electric vehicles can achieve 17% more range via even better recuperation of braking energy.

With dry, brake-by-wire systems in particular, the residual drag torques that occur with conventional braking systems due to minimal contact between the brake pads and the brake discs can be reduced to almost zero. This results in even fewer particulate emissions due to brake abrasion. This lower resistance during driving also saves energy and can increase range in an EV.

Dispensing with a hydraulic system means significantly lower assembly and logistics costs even during vehicle production, as the system consists of fewer parts. And during the vehicle’s service life, the user benefits because brake fluids no longer need to be changed, reducing the amount of servicing required in the workshop.

Even though there is no longer a mechanical connection between the brake pedal and the brake actuators, the braking ‘feel’ is the same as that of a hydraulic brake. The safety of the data transmission and processing as well as the energy supply to the electric motors is ensured by the duplication of all connections and systems, as is also common in by-wire systems in aviation.

Vehicle manufacturers can put together their optimum braking system from the classic purely hydraulic to the new purely electric braking system depending on their requirements. Hybrid forms with, for example, a hydraulic system at the front and a purely electric system on the rear axle are also possible. In addition, ZF offers all components of a braking system from a single source, from wheel brakes to parking brakes, and hardware to software.

- ZF has now confirmed that it has no plans at present to introduce the new system to heavy vehicles