New motor: rare-earth free and greater efficiency

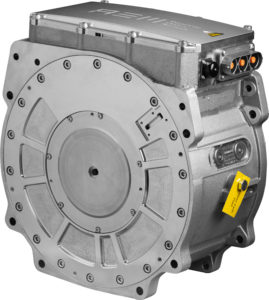

Advanced Electric Machines (AEM), the UK-based manufacturer of sustainable, magnet-free electric motors, has unveiled its latest heavy duty motor for electric vehicles.

The second generation of AEM’s solution for heavy duty and commercial vehicle applications, HDRM300C is designed to provide customers with an enhanced motor that offers stronger performance and greater efficiency than its predecessor. The previous generation of its motor is used in bus applications manufactured by INKA in Indonesia.

Building on the success of its HDRM150 motor, where AEM first developed and validated its coil compression technology, the company says the HDRM300C represents a major advancement in electric motor design, achieving conductor slot fill rates exceeding 80%. This proven technology, now evolved and scaled up from the smaller HDRM150, delivers measurably better power density and efficiency compared to conventional wire layouts that typically achieve less than 60% fill rates.

The HDRM300’s increased speed capability provides greater flexibility for system integration across diverse applications. New plug-in connectors have replaced traditional gland fittings, intended to simplify the installation and maintenance process, while maximising overall reliability. Internal components, including upgraded bearings and robust busbar connections, have been strengthened to support the motor’s higher operational speeds.

An improved motor cooling system, which works similarly to a car’s radiator, is designed to allow the machine to work harder for longer without overheating. This should translate to the vehicle carrying heavier loads, climbing steeper hills and operating in more demanding conditions without compromise.

Sample units will be trialled with select partners from March 2025, with full production scheduled to commence in Q4 2025.

“For the transportation industry, this means more capable electric vehicles that are more cost effective to operate and maintain” – James Widmer, CEO of Advanced Electric Machines

James Widmer, CEO of Advanced Electric Machines, said: “The HDRM300C represents more than just an incremental improvement in motor technology. By combining our patented coil compression technology with enhanced thermal management and improved speed capabilities, we’re delivering a motor that sets new benchmarks for efficiency and performance. For the transportation industry, this means more capable electric vehicles that are more cost effective to operate and maintain.”