Keeping air-con’ hygienic – MAN advises

As the industry prepares for passengers to get back onboard, ensuring maximum hygiene for both staff and passengers may well be high on the agenda. However, how much thought has been given to air-conditioning system hygiene? Here, MAN Truck and Bus gives drivers and operators some recommendations. Heinz Kiess, Head of Product Marketing Bus at MAN Truck & Bus, explains what exactly bus operators and drivers should now keep in mind to minimise the risk of infection in the passenger area.

What should be done to minimise the risk of infection?

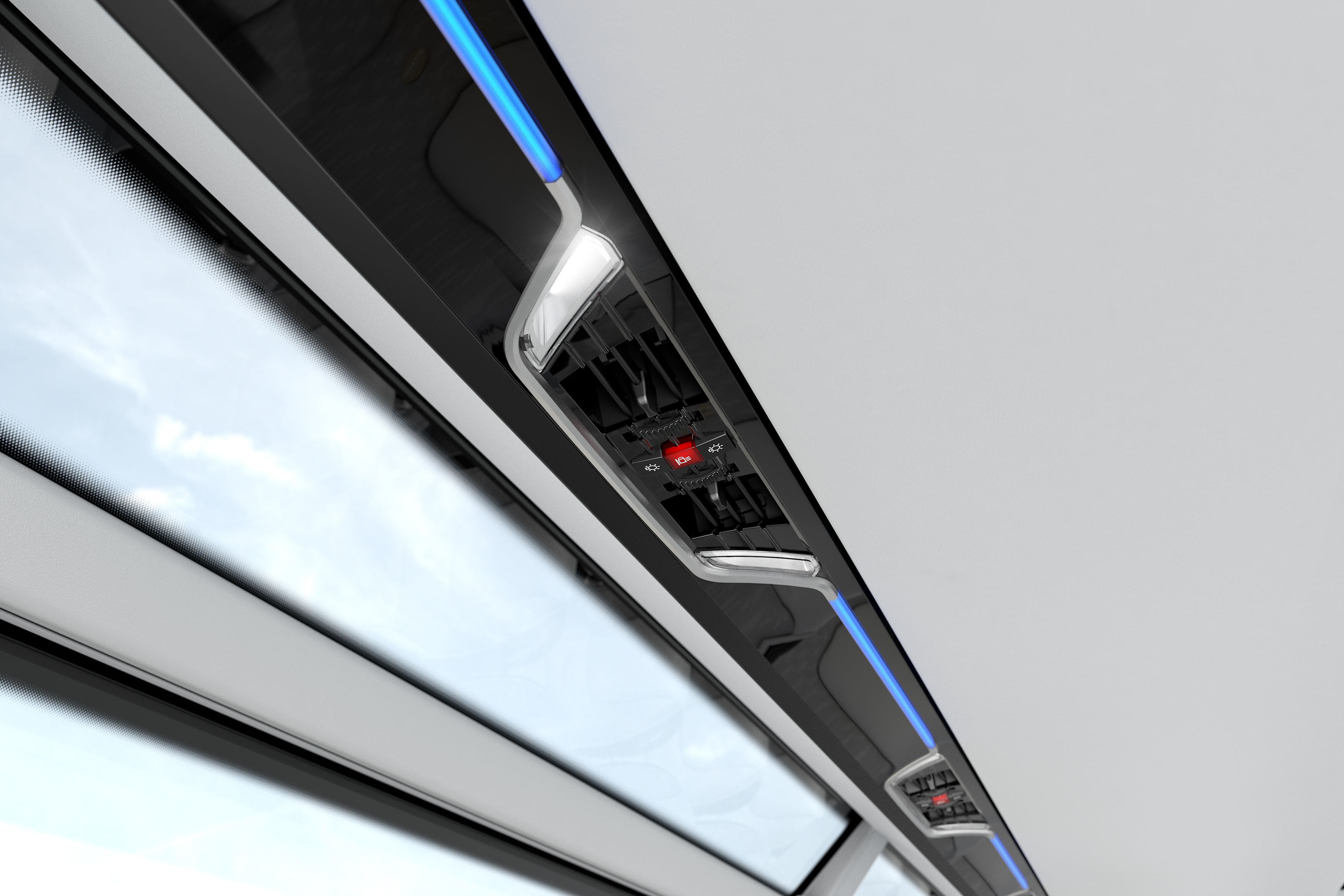

Heinz Kiess: “Drivers and operators should take various measures to reduce the possibility of the virus spreading throughout the passenger area in the bus’s air-conditioning system. Firstly, the air-conditioning system should only be used in fresh-air mode – where possible – and without re-circulation. Also, the system should not be manually deactivated using the switch, as this only shuts off the refrigerant compressor and not the blower. To avoid reducing the amount of fresh air in the passenger area, the blower speed should also not be manually decreased. For buses with service sets, we recommend closing these before the start of a trip. This can help to put passengers more at ease, as they will no longer be hit by a direct flow of air. Instead, the air will only come from the vents in the roof duct. To increase air purity, the interior air filters in the roof-mounted air-conditioning system and the front box should also be replaced at regular, short intervals.”

How does a bus air-conditioning system generally work?

Heinz Kiess: “The set-point temperature in the passenger area is regulated using heating elements in the passenger area: these are situated both under the seats and on the side walls. The front box and roof-mounted air-conditioning system also help to maintain the set-point temperature. With these, the proportion of fresh and recirculated air is regulated according to the ambient conditions using ‘passenger area control’. Here, the air is filtered through interior air filters installed as standard and, to some extent, with activated carbon filters. Further on, the used air is discharged through separate ducts. With active ventilation, the used air is permanently purged from the vehicle interior through these ducts, which guarantees seamless air circulation.”

“In theory, we cannot entirely rule out the possibility of coronavirus infection due to the bus air-conditioning system” – Heinz Kiess

How high is the risk of infection posed by the air-conditioning system?

Heinz Kiess: “In theory, we cannot entirely rule out the possibility of coronavirus infection due to the bus air-conditioning system. However, we estimate that the risk is very low. Other factors – mainly a failure to observe the general hygiene and distancing rules in effect – pose a much higher risk of infection. This is why recommended regional, national and international safety measures stipulated or recommended by the relevant authorities should be adhered to in buses as well. In addition, bus drivers and operators should ensure that grab handles and poles in particular are regularly disinfected. We also think it’s very sensible to practise good hygiene and provide sanitiser by the bus entrance.”

Are there other protection measures especially for drivers?

Heinz Kiess: “Many manufacturers and operators are currently considering dividing the driver’s cab from the passenger area with a pane of Plexiglas or something similar. This should provide more dedicated protection for drivers. Some solutions like this have already been implemented. We are receiving more enquiries in this regard, especially from the market for city buses. For our new generation of city buses, we will shortly be in a position to offer a protective screen for the driver’s workplace as special equipment installed at the plant – and as a retrofitted solution through After Sales. We have also received enquiries for all other vehicles operated by our customers, such as intercity buses. In the MAN Bus Modification Center in Plauen, we can quickly implement custom solutions for specific cases. There are already a few ideas for coaches being developed in close cooperation with the respective companies. At present, the regulations and specifications on an international level are very inconsistent, which is why we are trying to discuss and implement good ideas that transcend national borders.”