Five in the spotlight

To see the HUGE gallery of images, just click on the banner photo above, then cycle through them with the arrow

After a hiatus in 2023 when no test was staged, early May saw the International Bus & Coach of the Year Jury back at work putting the latest zero-emission bus designs through their paces in the Czech Republic.

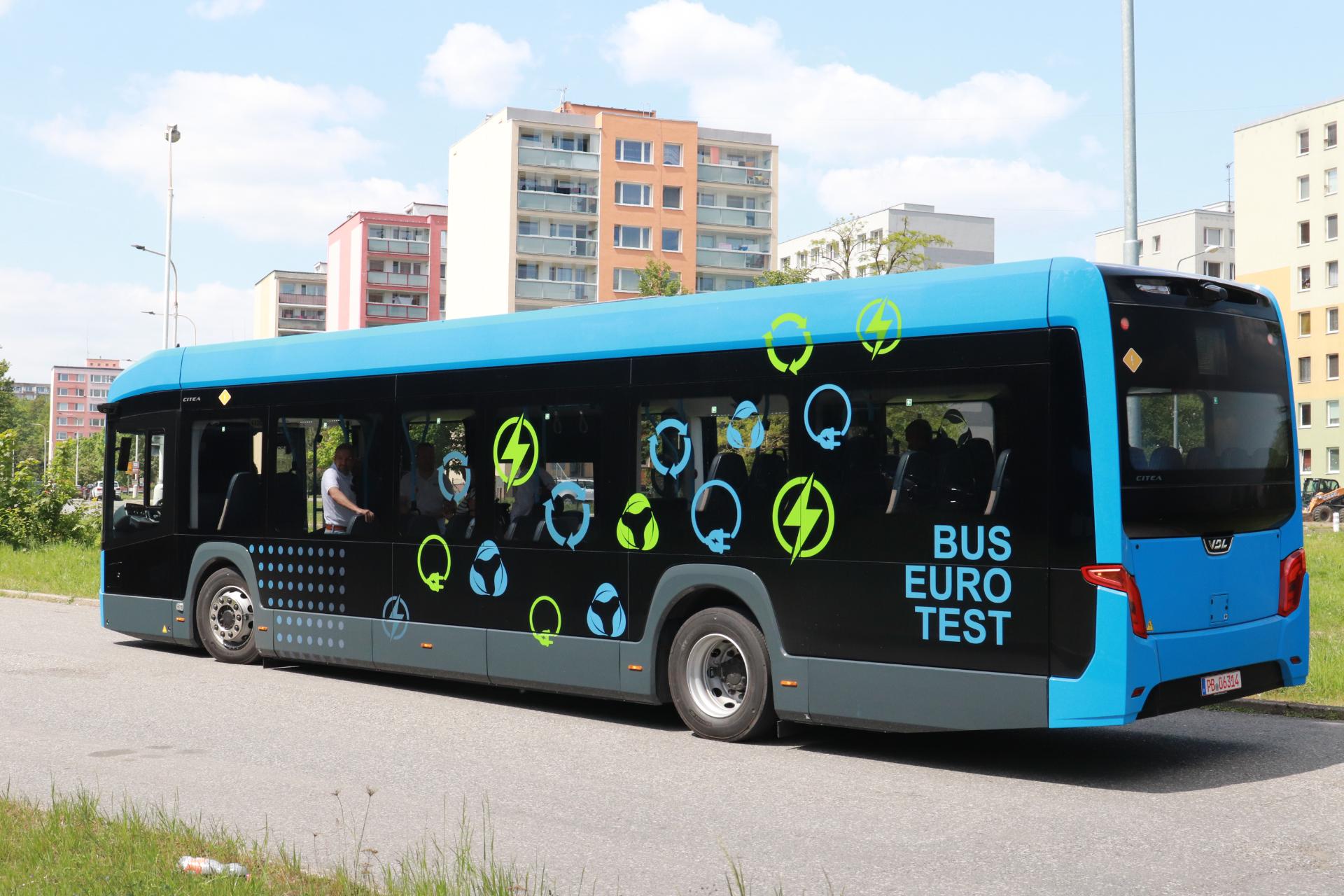

Based at the Kladno depot of Arriva’s CSAD MHD Kladno subsidiary, near to Prague, and organised by Michal Stengl of the magazine Transport-Logistika, the event facilitated the election of the International Bus of the Year 2025, the winner of which will be announced in September. Five competitors entered, each with different characteristics. They were the Mercedes-Benz eCitaro Fuel Cell, the articulated Solaris Urbino 18 Hydrogen, the VDL Citea LE122, the 18m articulated Ebusco 3.0 and the MAN Lion’s City 12E LE.

The Jury represents magazines from 25 European countries and has just appointed a representative from Turkey. All are respected transport professionals and together they look at the candidates in depth. In the Czech Republic, after braking and acceleration tests were carried out at a nearby airport, jurors experienced each bus as a passenger and, if qualified, as a driver on a predetermined 14.3km route that gave a balance of relevant conditions. In addition, each manufacturer gave two presentations, one in a meeting room and the other in and around the bus, to explain each vehicle’s main features. This year’s braking tests were somewhat hampered by torrential rain.

Although the juror’s magazines fund their presence, the main evening dinners were, as is customary, sponsored by Busworld and ZF and were convivial evenings that highlighted the culinary delights of this most exquisite of cities, not to mention the excellent beers.

Mercedes-Benz eCitaro Fuel Cell

Intro

While the debate continues over whether electric or hydrogen is the way forward, Daimler has introduced a development of the Citaro that combines the driveline and batteries of its eCitaro with a Toyota produced fuel cell stack to provide a range extending option giving the bus a total range of ‘around 400km’. Massively well regarded in Europe and beyond, Mercedes-Benz has already supplied over 1,000 eCitaros since the first production examples were delivered in 2018. The 18.1m articulated hydrogen fuel cell range extender version was launched last Spring and the 12.2m Solo bus version followed at Busworld further enhancing the Citaro range (pun intended).

Interior

A dual entrance bus with a portal rear axle, the eCitaro Fuel Cell featured a centre door ramp with a wheelchair bay opposite the centre door. It had 31 fixed seats (four of them extra wide) of which eight faced the rear, and 14 were accessible directly from the low floor section. In addition, there were three tip ups in the centre. Despite the low floor rear axle, all seats beyond the centre door are accessed via podests/steps so in this respect there is little advantage over low floor designs, although it does enable a third entrance option in left hand drive markets. Where possible, cantilever units were used. The maximum capacity possible is 88 passengers.

Quality and finish were good. Unlike most other electrics on the European market, Mercedes-Benz has yet to launch a completely new platform for its zero emission bus products (rather than one developed from existing diesels), one result of which is that the eCitaro and the eCitaro Fuel Cell retain the full-height, boxed-in, cupboard in the offside rear corner. This reduces seating capacity and makes the rear of the saloon darker and slightly claustrophobic. Mercedes-Benz point out that there are advantages to its retention in, not least in weight optimisation.

A real plus point for the bus was the perceived quietness of the ride, although measurements taken near the drive axle suggested the MAN was slightly quieter. It felt very solid and there was no window shimmer on the road

A benefit of the fuel cell is that its heat producing components are integrated within the bus heating system to help heat the interior. For this reason, the system uses R134a refrigerant rather than CO2. The system has four separate circuits, one each for the fuel cell, HV battery, high temperature and low temperature circuits.

As well as the advanced driveline, the bus bristles with safety features, some going beyond the safety directive. Among these are rear view camera, alcolock, attention assist, tyre pressure monitoring, traffic sign assist, front guard assist, sideguard assist 2 and Brake Assist 2. Assisting with these are new long and short range radar systems and a multi-purpose camera.

Driveline

Electrical drive uses the popular ZF AVE130 low floor portal drive axle incorporating two, liquid-cooled three-phase asynchronous electric motors near to the wheel hubs. Operating at 400V each unit has a continuous output of 87kW and a peak of 125kW, each delivering maximum torque of 485Nm and maximum torque at wheel of 11,000Nm. There are three high voltage battery blocks (one on the roof, two at the rear) each with a capacity of 98kWh giving a total capacity of 294kWh. Each of the nickel manganese cobalt (NMC3) blocks weighs 600kg, operates at 665V and is liquid cooled. Depot charging is employed with CCS charging socket above the front axle on the right. There is an inverter for the high voltage auxiliaries and a power inverter to turn the direct current into three-phase current for the drive motors as well as recuperation of the current generated in the wheel hub motors.

The fuel cell is the second-generation Toyota heavy duty unit with a maximum output of 60kW, weighing in at 240kg. and operating at between 400 and 750V. The hydrogen to fuel it is stored in five roof-mounted type-4 cylinders, each holding up to 5kg at 350 bar for a total capacity of 25kg. The filling point is above the second axle on the right. Significantly, the fuel cell has a 40,000-hour design life.

ZF also supply the front axle, an RL82EC independent unit with an eight-tonne capacity that, as at the rear, employs 275/70R 22.5 Pirelli tyres.

Driving

For the driver, the only difference (from diesel fuelling) to note is that the vehicle needs earthing during filling if the pipe does not do this automatically. In theory, you can charge the batteries and the fuel cell simultaneously, although, as Daimler pointed out, ‘You won’t find anywhere where both are together.’

To garner driving impressions, I teamed up with the Romanian jury member, Cristiana Sandulescu of Tranzit magazine who found it no different to driving a battery electric, with the same driving position and acceleration. She particularly liked the option to choose whether to either roll or have a small amount of braking when you release the accelerator and was similarly impressed with the 360-degree camera. The stick and pedal retarder worked progressively and all switches and controls were easily to hand.

Other jurors felt that the bus sometimes felt slightly top heavy over the front axle and others complained that the sideguard feature sometimes gave false readings when there was no obstacle. Perhaps surprisingly, as camera mirrors are an option, it had traditional mirrors, though these were liked by some jury members.

Final points

I do not know what the cost of the vehicle is, though I did ask, but with a fuel cell and a full electrical drive electrical system it will inevitably be pricey. Thinking in UK terms, arranging charging facilities for an electric bus is already challenging – providing additional facilities for hydrogen as well will be even more of a headache. Should you not be able to source hydrogen at any time, it can be run in purely electric mode, which increases flexibility. And with battery technology improving all the time, one questions how many routes there are that will have sufficient need for the dual technology to justify the additional cost and complexity. Technically it is impressive and the first examples have been delivered, but in the long term I am yet to be convinced that it will be a major seller.

Solaris Urbino 18 Hydrogen

Intro

Solaris believes hydrogen is the sector of the zero-emission market that is growing the most dynamically. It is not claiming that hydrogen will fully replace electric propulsion but believes that for those who require very long range (600km) the ability to fully recharge in 20 minutes is a draw. The range could be increased to 800km but this would reduce the maximum 140-passenger capacity significantly. Solaris has already delivered 200 Hydrogen buses and has a further 600 scheduled for delivery over the next two years to a total of 40 customers.

The second hydrogen powered entry in the test, the Solaris Urbino 18 Hydrogen is a four doorway ‘pusher’ artic, the ‘pusher’ concept selected because with a central motor it provides the most space for passengers. It uses the hydrogen as its primary fuel, rather than as a range extender, supplying the power to an electrical system with 140kW air-cooled central motor that drives the third axle. There are two small battery packs with a 60kW capacity, but these are only used at peak demand. These normally charge directly from the fuel cell although there is a plug-in socket for service mode.

Unlike the 12m Urbino 12 Hydrogen, the Urbino 18 Hydrogen has no stack in the back corner, because it employs new modular driveline technology in place of the former central unit. Aside from the additional interior space, the main advantage comes in being able optimise the layout and the weight distribution with benefits for handling characteristics and capacity maximisation.

Interior

Quite classy and the same time bright, the Urbino saloon featured wood effect flooring, big windows, polished stainless steel stanchions and rails, a reflective driver’s cab door and lots of lights integrated within the vertical stanchions as well as light up bell pushes.

Badged Solaris, the seats were Ster 8MU units, most of them cantilevered. Although 140 is the maximum possible, our bus was certified for 128 passengers (44 seated/84 standing) or 122 (44/78 plus one wheelchair). Many were mounted on pedestals, especially in the rear section where there are three steps up to the rear and penultimate seat row, which is not ideal but is much preferable to having a rear corner stack. All podiums and other protrusions had rounded corners and all edges featured robust yellow finishings to help make them more obvious to users.

Also new is the front, the destination display unit, the roof covers, and the front LED light system.

On the road the bus had a solid feel and yet panel replacement or repair was particularly easy to accomplish.

Driveline

The previously mentioned modular driveline concept sees the various components placed on the, now somewhat crowded, roof and below the rear section of the trailer in a manner that helps balance axle loadings. On the front section there are five 312-litre type IV hydrogen tanks placed longitudinally at the front, with another three 194-litre tanks further back, across the width of the bus. The combined capacity of these tanks at 350bar is 2142litres/51.2kg and they are 20% lighter than the previous generation type III tanks. Between the tanks is a CO2 air-conditioning unit with heat pump and at the rear of the forward section are the 60kW Solaris high power LTO traction batteries. On the rear roof section, the fuel cell, and its radiator as well as the BTMS are ahead of the rear, with the second CO2 air conditioning unit with heat pump over the axle and at the rear the braking resistor and DC/DC converter. This resistor and convertor form part of the MEDCOM modular drive, the other main components of which are the 24V DC charger, traction inverter and HV Box which are located below the floor at the rear. The central motor is located to the rear of the rear axle driving directly into it. A 240kW unit, the motor delivers that output continuously giving continuous torque of 1,470Nm and peak torque of 1,222Nm.

Ballard supplies its eighth generation FCmove HD+ 100kW fuel cell which cold starts unassisted at temperatures of 25 degrees centigrade and operates in the temperature range -30 to +50 degrees C. Refuelling the bus fully takes around 20 minutes, we were told, and testing had revealed hydrogen usage of 6.5kg/100km. The cell is designed for an operating life of 30,000 hours.

Driving

Cristiana enjoyed driving the Urbino which felt like a diesel. ‘It didn’t feel electric because it didn’t have the squeal specific to electrics’ she said. When you accelerate the dash display shows how you are using hydrogen and when braking it shows how much energy is being saved. ‘The energy stored in the supercapacitors gives more power when pressing the throttle – it really has good power,’ she said. The camera mirrors worked well.

The only thing that bothered her was that it takes different angles to the Ebusco artic (a puller) requiring her to really pay attention to avoid catching the centre axle on the side of the road. Either standing or hanging pedals can be specified, this had a standing accelerator.

The first prototype of the model built; it did not have all the GSR features that will be standard on production models. Nevertheless, she liked the centre dash display which enabled you to easily switch between screens to check features such as door status and braking usage. To the left of this a digital speed display and to the right details on recouperation and hydrogen use. At the bottom features include: energy in the supercaps, remaining range and inside/outside temperatures.

Final points

Hopefully the rest of Europe is experiencing less difficulty in accessing hydrogen supplies than some UK operators because Solaris is supplying a lot of hydrogen fuelled buses. Whether down to environmental concern, range, preference, or the deficiencies in the electrical grid in existing depot locations, it is an option that clearly works, with the benefit of being much the same as existing diesels in terms of driving and refuelling, as far as the driver is concerned.

Emitting nothing but pure water is a big plus, especially if ‘green’ hydrogen is used, but one aspect that initially looks odd to the onlooker is the clouds of steam we witnessed coming from the back of the bus on the damp Tuesday of the test. I didn’t notice the phenomena at all on the sunnier days following.

Pricing was not revealed by Solaris but it was said to be ‘almost the same as electric.’

VDL Citea LE-122

Intro

Completely new for the zero-emission era, indeed there are no diesel versions, the first models in the latest VDL Citea range were unveiled two years ago. The designers were quite radical in what they set out to achieve and were unafraid to adopt new concepts, if they delivered advantages in areas such as weight, economy, capacity, safety and comfort. Perhaps the most radical diversion from previous practice sees the use of slim batteries mounted below the floor, while the glass fibre sidewalls save 650kg compared with earlier Citeas. Rear wheelarches sculpted to reduce turbulence and drag air past, together with a rear spoiler and sharper edges contribute to a 22% reduction in drag. The front and rear profiles have been slimmed down, a significant element in achieving the 45-seat maximum capacity that is an improvement on the 41-seat previously possible. The bus tested had 39 seats and two tip-ups.

Initially made available as a full low floor option, the low entry 12.2m long Citea LE-122 was first shown at Busworld last year. It is the first low entry model in a range that will also include the LE-135 13.5m (two-axle) and LE-149 14.9m (tri-axle) low entry alternatives alongside the existing LF-122 12.2m and LF-181 18.1m low floor models. At 105, the LE-122’s maximum passenger capacity is greater than the 89 of the longer LE-135, though this can offer more seats.

Interior

Of all the interiors, this was the one that most impressed me as a passenger, especially at the rear, though I think there are further steps forward to be made on the noise. It brings a new meaning to the concept of light and airy, with big windows, an arched wood effect ceiling, LED lighting, mood lighting below the windows, light colours, space and ease of cleaning. There are two distinct zones in the interior, the front low floor area and the rear saloon beyond the centre door, accessed via two steps. VDL research shows that those who travel at the front are typically older and prefer the bus to be warmer while those who choose to travel at the rear like it cooler. Acting on this, they have made the mood lighting below the windows red at the front and blue at the rear and programmed the climate control to make the temperature two degrees warmer in the front zone than the rear.

Although two door in-swinging or out-swinging doors are offered, the bus shown had an unusual arrangement, designed to increase the efficiency of the climate control system, whereby a section to the rearmost side of the forward door aperture is a fixed glazed panel with passengers entering through a single leaf rearward opening outswing door. The centre door is a two-piece unit. Incidentally, there is a safety feature on the kneeling system (on this bus front axle only) that prevents outward swinging doors functioning if deploying them would mean them fouling the pavement.

Little touches included the incorporation of Smart phone holder on the seat backs, which will no doubt impress a younger generation, though it may also increase the workload of the lost property office.

Not only passengers, but cleaners too will like it, because the cantilevered seats (which can be equipped with seatbelts) make cleaning straightforward with minimal inaccessible places where dirt can collect. Window sills have been shaped so that no dust will collect. Using the cleaning menu selected on the cab display, the dash lights up to enable five fluid levels to be checked.

Driveline

In common with the other candidates VDL relies on ZF for its drive and axles, the LE 122 having the ZF CeTrax drive system with combined asynchronous motor and gear reduction unit driving through with the ZF A133 axle via a direct driveshaft.

The VDL High Energy battery packs use bought-in cells and have a total capacity of 490kWh, 306kWh from batteries beneath the floor. Less than 490kWh can be specified if less range is required. In a real-life test conducted with simulated loads in September last year, a Citea covered 546.7km in 26 hours without recharging, at an average speed of 21km/h.

Although there is no current VDL option, we were told that the platform was designed to be suitable for hydrogen ‘if it became important.’

Driving

Protecting the driver to the rear is a cab partition that we were told wouldn’t break or shatter if it was attacked with a hammer, though a request to demonstrate this for ourselves was rebuffed. VDL has put a lot of work into ensuring the driver can find exactly the right position to drive comfortably, and the extent to which you can adjust the height and rake of, not only the steering wheel, but also the whole binnacle is probably greater than on any bus I have seen before. The adjustment is enabled by the push of a button that locks in place after 15 seconds. To exit the cab, you must know where the hidden door release button is, or the substantial cab door will not open. Drivers better hope they cover that during induction.

Among my colleagues there was widespread praise for the driving experience and for the thought that had gone into designing the cab. Cristiana described the driving experience as ‘brilliant,’ finding it smooth and comfortable, with steering neither too hard nor too soft. I do not suppose many will specify it but she liked the leather steering wheel cover and found the driving position very easy to personalise. Power was good, as was the suspension, and she liked the new colour digital instrument display which showed what you wanted to know when you needed it. One criticism was that she found the stalks were mounted a little too high for her, which made them more difficult to use when cornering. The A pillar being further back added to the field of view and the camera mirrors gave a good image.

Final points

The Citea range can be built either at Valkenswaard in the Netherlands, as this bus was, or the newly opened plant at Roeselare in Belgium. Investment in that plant shows the level of confidence that VDL has in the future of the new product range.

Ebusco 3.0 18m

Intro

Ebusco has a product range not widely known in the UK, but one that has been picking up tender wins over the past few years and has a growing European vehicle parc, including the German capital, Berlin. At the end of 2023 it had an order book for 1,700 buses including 700 3.0s, 260 of them articulated. Based in the Netherlands, with a second plant in France and assembly partners in China and Portugal, Ebusco uses predominantly European parts except for the batteries. The latest 3.0 family of buses seeks to minimise weight using carbon fibre composites in the body construction and achieve a low centre of gravity (860mm), as well as a spacious low floor interior, by mounting the slim batteries below the floor. Construction sees an inner body skin and an outer body skin with pillars between and foam injected into the wall panels. There are no side flaps. Also offered as a 12m or 13.5m solo bus, the version entered was an 18m articulated bus.

Although it claimed an unladen weight of 14,900kg on the exterior I understand the actual ULW was close to 15,020kg. The bus did not participate in the braking and acceleration tests because of an issue with the low voltage electrical system that was resolved on the day enabling it to join the rest of the field for the main testing days.

Interior

As entered, the super-lightweight vehicle vehicle’s capacity is 100 (49 seated/51 standing) or 45 seated, 53 standing and two wheelchairs. A capacity of up to 150 can be provided on the 3.0, 500kWh long-range model but this requires a switch to twin or super twin drive axle tyres. Kiel Ideo seats were specified and those not on podiums or wheelarches were cantilevered, a standard feature. A four-entrance design (three is an option) it had the wheelchair bay located on the offside opposite the second door with two tip up seats and a folding carer seat. All doors are supplied by Ventura.

The interior was tidy and functional with blue seat trim, contrasting yellow stanchions, deep windows, light grey plastic panels and a darker grey floor, but finish was a bit lacking in some places on the large grey plastic panels. Gangway width is 900mm throughout. As an early example of the type, the bus had plastic decency partitions that shimmered noticeably. Production buses will have glass ones instead.

On the road it was quite noisy, the noisiest of all the candidates, especially at the rear of the forward saloon when decelerating/recuperating and during the early stages of acceleration, when there was a pronounced whistle at times. Sat over the rear axle I experienced considerable vibration. I found the air conditioning a bit overenthusiastic too.

Driveline

Unusually, among modern artics, the 3.0 is a ‘puller’ design with the second axle driven and a non-steering rear axle. The 400V three-phase AC electrical system has two motors near the axle, each providing maximum power of 125kW for a total of 250kW. Maximum torque is 22,000Nm. All three axles are ZF.

The cobalt-free LFP (Lithium Iron Phosphate) batteries were developed in conjunction with the Chinese company, Gotion who have a plant in Göttingen, Germany. Arranged in strings, each battery pack has a total capacity of 127kWh, our bus having three packs (two at the front and one at the rear) for a total of 383kWh. It is possible to have four packs giving 511kWh on the artic, which is said to give a range of ‘up to 700km’ though the literature on the 383kWh only claimed 450km. Each of the battery packs is 12cm high and they are warrantied for ‘up to eight years’.

Driving

Possibly because it is lighter, Cristiana thought the handling of the Ebusco was very good for an artic, with excellent manoeuvrability and good power.

What she did not like was that the space between the wheel and the mobile part of the dash was very small and no matter how she adjusted it she was unable to see the bottom third of the display including details of remaining battery capacity. Information on speed was shown digitally as well as instantaneous details on energy consumption which displayed as a minus figure during regenerative braking. Visibility through the digital mirrors, which are standard, was good but it was noisy.

Another of my colleagues noted that with some setups of the adjustable steering wheel it was impossible to close the cab door, and others found the cab cramped.

Final points

Ebusco’s own data claimed that over the two days of the on-the-road driving tests the bus covered 261km and had 49.6% battery charge left, consuming 28.4% covering 145km on the first day (an average of 0.76kWh/km) and 22% over 116.7km on the second day (an average of 0.73kWh/km).

Ebusco’s claim is that the low weight will bring low total cost of ownership and there is also the suggestion that the construction may lead to a longer in service life of up to 25 years, presumably at this stage on its third set of batteries. Certainly, the innovations incorporated have the potential to make buses of this concept more economical to operate. I will be interested to see how many 3.0s have a third set of batteries installed because I did not feel the overall quality of the finish was up to that of the other candidates.

MAN Lion’s City 12E LE

Intro

MAN’s entry was the latest two-entrance low-entry derivative of the attractive Lion’s City family of electric buses, the full low-floor version of which won the 2023 International Bus of the Year title following the Bus Euro Test held in Limerick, Ireland in 2022. MAN’s zero emission range has been attracting strong sales in Europe and the bus low entry LE version shown in Prague carried bold vinyls proclaiming ‘No 1 in Europe’. MAN is focused on battery-electric power for the future and from 2025 will equip them with its own Nuremberg-built batteries. The range will include a right hand drive bus chassis.

Body

Built to Class 1 city specification, the bus featured MAN City Comfort seats. The maximum seating capacity possible is 41 plus wheelchair, 37 of them forward facing. It featured large over-seat luggage racks in the low floor area. Though I liked the many small cut-outs in the rack underside that make locating your luggage easier, they are mounted so high that despite being six feet tall I was unable to retrieve anything from them, a result of legislation dictating the amount interior space that must be maintained in a rollover. This combined with grey wood effect flooring, vertical metal-finish stanchions that curve in at the top and link every seat with the ceiling, as well as exterior promotional vinyls that partially obscure the windows, made the bus feel more enclosed than some of the others.

The approach was very different to that of the other low entry bus entered, the VDL, in that the wheelbase was shorter at 6.005m, the raised section was one seat row longer, with a consequentially shorter low floor area, and the seats in the rear were not cantilevered but floor mounted on podests with wide metal side plates that will hamper the cleaning process. The MAN does not have the rear corner stack, once common on European city buses, but to accommodate a low roof section above, the rearmost seat is set slightly lower than the others. Having bumped my head once, I found access more difficult than elsewhere on the bus. Seats were trimmed in an attractive blue/grey/black material and elsewhere the bus was trimmed in shades of grey.

In the low floor area, the large wheelchair bay is on the nearside, ahead of the centre door, and had no tip up seats. Aside from this bay, there are only the raised double ahead of the wheelarch and the rear-facing floor-mounted double beyond in the nearside low floor area. On the offside, there are four forward-facing and one rear-facing floor-mounted double seats as well as a raised double behind the driver’s compartment.

With two twin-leaf outward-opening electric doors, drivers had to be careful at stops as the forward leaf of the front entrance swung out and protruded beyond the front of the bus when fully open. A manual ramp was fitted at the centre door with push buttons for those needing it to inform the driver. Air conditioning was by means of a CO2 Valeo electric air-conditioning system with integrated heating facility.

Driveline

MAN’s driveline consisted of an MAN central motor rated at 160kW(218hp) continuous and offering peak power of 240kW (326hp) mounted on the rear axle. Continuous torque is 1,300Nm and maximum torque 2,100Nm. There is a single stage MAN adapter gearbox enabling the driver to use the familiar DNR buttons.

Operators can choose battery capacity dependent on intended use and range required in increments of 80kWh, this example having the maximum six battery packs giving a total capacity of 480 kWh. Mounted on the roof, the water-cooled battery packs use Lithium-Ion (NMC) technology. Additional charging options are coming but currently depot charging at up to 150kW using a CCS plug is standard. Two charging points are provided on the right of the bus, at the rear and over the front axle. Charging time is up to four hours.

The on-board 24v electrical system has two 230Ah batteries with battery protection shutdown via an emergency stop switch.

The rear portal axle is the MAN HU-1330-B-00 with a i = 5.12 ratio. Mounted on 275/70 R22.5 tyres it gives a permissible axle load of 11,500kg. At the front is the independent MAN VOKS-08-B-01 ERA axle system. Suspension is by means of the ECAS air system with lift limitation and PCV shock absorbers.

Driving

As UK operators are probably already aware, MAN has been introducing its Model Year 2024 package across the range and the e12LE benefits from it. It includes a new digital cockpit with a new climate centre, a 12-inch driver’s display, new switches, and multifunctional steering wheel. It enables and fulfils the requirements of the European DSR safety legislation providing advanced assistance systems including ESP, turn support and lane change support, emergency brake assistance, and cruise control.

Cristiana was positive about the driving characteristics finding it a comfortable bus to drive and noted the array of GSR safety features. She was less sure about the automatic slight deceleration of 200Nm that comes in as soon as you take your foot off the accelerator, but liked the retarder on the stalk which operates very smoothly.

Once acclimatised to the monitor positions, she liked the OptiView digital mirror system which was very good, showing the whole of the front and the right side.

Final points

Although this was a Class 1 e12LE bus, a class 2 intercity specification with seatbelts, floor hatches and ECE R66.02 rollover certification, is to follow this autumn. Also scheduled for the electric inter urban market are a low-entry 13m two-axle bus and a 14m tri-axle low entry as well as, from 2028, the eLow Entry Cross Country specification 12-14m range on two and three axles and 295 rather than 275 tyres. Next year will see a major upgrade on the e12LE with it receiving not only MAN’s new in-house batteries, but also new charging options including 375kWh charging and an inverted pantograph option, but also a new e-axle as well as weight distribution improvements.

Conclusion

Whether you believe hydrogen, battery electric, trolleybus, or something else is the long-term best solution, events in Prague showed that the European manufacturers are developing the necessary hardware to serve the need, and that hardware is very impressive and full of innovative ideas. Early concerns over range are dissipating somewhat as battery technology improves and experience shows what can be achieved.

It is perhaps a pity that there were no products of the Chinese manufacturers taking part, because not only would it have been interesting to compare their performance, but also because, as we have seen in the UK, it is they that may represent the biggest threat to the long-term prospects of our European manufacturers.

The winner will be revealed in mid-September and the prize awarded at the IAA Exhibition in Germany.