Cummins develops hydrogen internal combustion engine tech

Cummins and key technology partners have developed hydrogen internal combustion engine technology for buses and trucks.

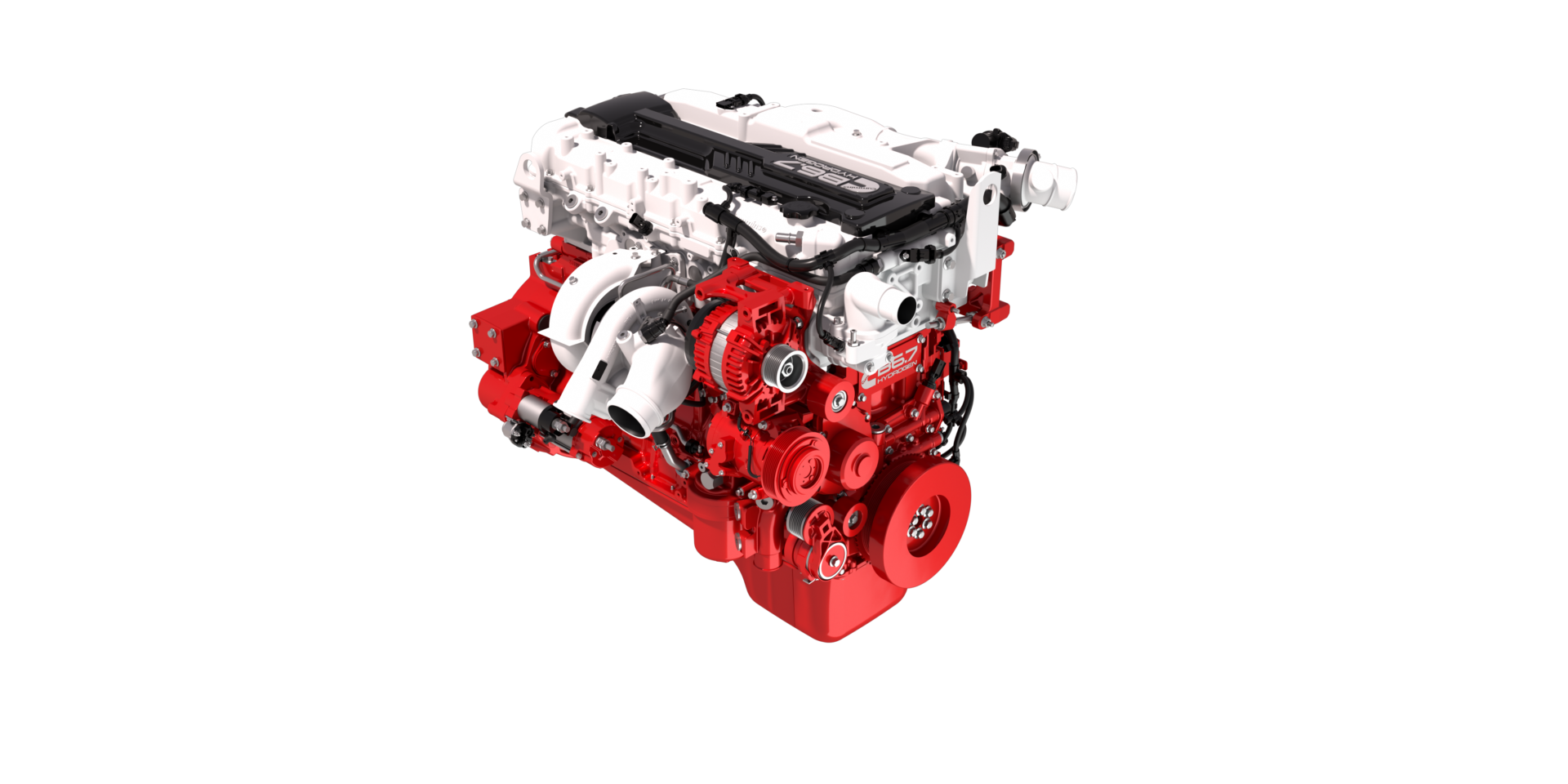

Cummins led a consortium of technology companies (Johnson Matthey, PHINIA and Zircotec) in ‘Project Brunel’, to successfully deliver a 6.7litre hydrogen internal combustion engine (H2-ICE) for medium-duty trucks and buses. The project was match-funded by UK government, and facilitated by the Advanced Propulsion Centre UK (APC).

Together, the project partners developed a hydrogen internal combustion engine concept based on Cummins’ proven spark-ignited engine platform. Underpinned by new hydrogen fuel injection technology from PHINIA, after-treatment catalyst and advanced metals chemistry development from Johnson Matthey, and hydrogen barrier coatings from Zircotec, Project Brunel has delivered significant improvements in H2-ICE engine performance and durability.

Using zero-carbon hydrogen fuel and equipped with an after-treatment system, the 6.7-litre engine delivers a more than 99% reduction in tailpipe carbon emissions and ultra-low NOx, compared to Euro VI diesel engines.

“We hope the Government recognises this technology’s potential for commercial vehicles beyond 2035 and 2040” – onathan Atkinson, Executive Director – Product Strategy at Cummins

Jonathan Atkinson, Executive Director – Product Strategy at Cummins, said: “Project Brunel highlights the power of collaboration between industry leaders and underscores our ongoing commitment to industry decarbonisation. This project has successfully delivered a viable, familiar power option that meets the operating requirements of today’s commercial vehicles – with zero-carbon fuel, and without the need for a complete vehicle redesign. This is a major achievement for Cummins Darlington, and for the UK’s hydrogen technology leadership. We hope the Government recognises this technology’s potential for commercial vehicles beyond 2035 and 2040, to align regulation with other major global markets.”

While the 6.7-litre engine was developed for medium-duty vehicles, the design is scalable to heavy-duty applications. Cummins is already developing a 15-litre hydrogen internal combustion engine for heavy-duty vehicles.

Cummins recently invested more than £13 million in a new Powertrain Test Facility at its Darlington Campus, which expands the company’s test capabilities to include full powertrains powered by advanced diesel, natural gas, hydrogen and battery electric technologies for multiple industries.