Iveco Bus has triple celebrations

Iveco Bus opens new Prototype & Testing Centre as Czech plant celebrates 130 years. B&CB’s Stuart Jones finds out more

Click the image above to see the full gallery of images

It is a big year for Iveco Bus with triple celebrations marking 50 years of the Iveco brand, 100 years of the Annonay city bus factory in France and 130 years of its biggest bus plant, Vysoké Mýto, in the Czech Republic. To celebrate this and witness the opening of the new Prototype and Testing Centre in the presence of the Czech Minister of Transport, European journalists were invited to Vysoké Mýto to see the facility and hear about its history. Within it, Iveco’s Crossway range, which currently accounts for 52% of the European Class 2 (intercity) bus and coach market, is built. Crossway accounts for 92% of the plant’s production, with that split 57%/43% between the standard floor height LD and the low entry LE variants. The other 8% of build slots are taken by the Evadys coach based on the same running units.

Czech Minister of Transport, Martin Kupka, with David Kriz, General Manager of Iveco Czech Republic and Martin Netolicky, Governor of the Pardubice Region at the opening of the new Prototype and Testing Centre

Plant

The biggest employer in the area with 4,400 staff and a further 1,700 local supplier jobs depending upon it, the Vysoké Mýto plant covers

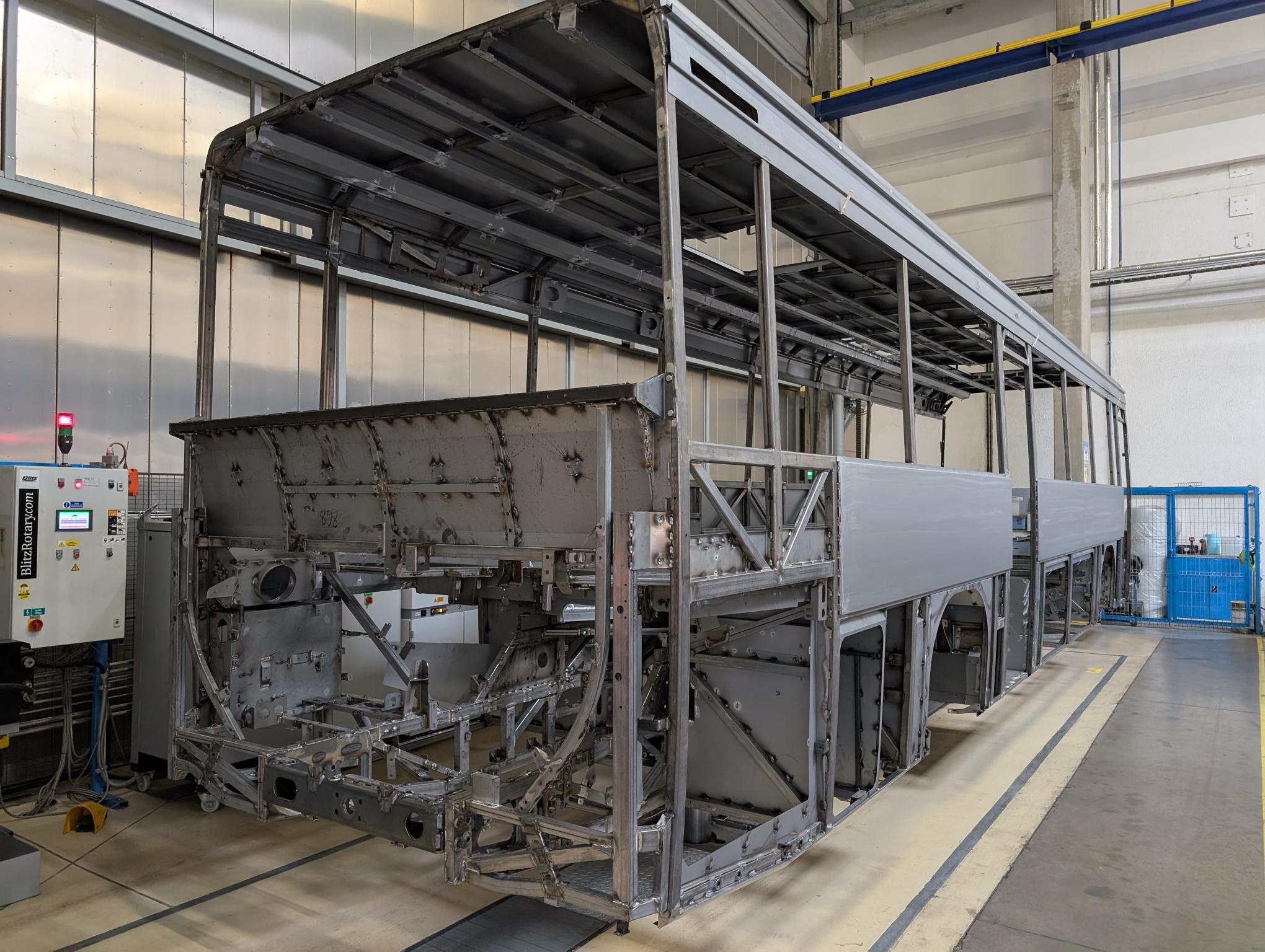

The cataphoretic dip process treats the entire structure against corrosion. It takes 13 minutes for each vehicle to go through this stage which involves total immersion

355,000sqm of which 135,000sqm is buildings. Manufacturing is heavily vertically integrated with metals for the structure and bodywork delivered and turned into components within the plant, using computerised laser cutting and bending machinery. This section of the factory, along with the paint shops works around the clock rather than on the two eight-hour shift basis used in the rest of the site. Iveco lists the on-site activities as: manufacturing, logistics, purchasing, engineering, quality control and customer customisation. Vehicle output is currently running at 22 vehicles a day.

After the metal incoming section, production shifts to the welding shop where the assemblies are welded together producing the sides, roof and underframe which are then assembled in marriage jigs. The process takes account of the many lengths, equipment and model variations offered and one and a half days after starting the skeleton of each bus is complete. Every bus is dipped in the cataphoretic dip process that takes 13 minutes and involves the complete submersion of the shell followed by baking at 200 degrees C. Laser cleaning with a pair of lasers that treat the surfaces of each vehicle reduces oxidation before painting. After the application of primer, the glueing of the panels, joint sealing, spraying the lower panels with an anti-abrasive coating, sanding and masking, the shell goes into the paint booths where the main colour is applied by robots. The latest process to be robotised is the sanding procedure. The whole painting process takes two and a half days.

After this each bus continues to the assembly lines, becoming more recognisable at each stage. There are three lines, some of which split in places. The first handles the items such as electrical harnesses that will be hidden at a later stage, the second seats, glass and all manner of items while the final line sees high value items such as engines and axles installed. Electrical vehicles, which are more complicated to build and have particular safety requirements for employees, are handled separately in a corner of the assembly hall, before rejoining the lines. Finally there is the finishing section. Vehicles of all models, whatever their propulsion system, proceed down the same lines. Next to the lines are the storage areas were the parts for each station are replenished by a busy fleet of fork lift trucks. Throughout the process there are quality gates and procedures designed to ensure quality. The whole manufacturing process from start to finish takes around 9.5 days per bus, with each bus successfully completing a 50km road run before it is allowed to leave the factory.

The laser cutting and bending machinery operates round the clock preparing components for the plant

Some 1.5kms away from the main production lines in a plant that is part of the founder’s original factory, 90% of the seats used are manufactured. Staffed almost entirely by women, the factory manufactures around 1,100 seats a day over two shifts. Four types of seats are made, in 36 colour variants using 700 types of fabric. Rows of ladies sit at sowing machines, while others operate two CNC cutting machines, assemble the steel frames, glue padding and plastic wrap the finished items. The constant rattle of staple guns makes it sound a bit like a war zone. Overhead television screens show the number of each bus being supplied that day, giving the details of exactly how many of each seat type are required. A one-day buffer stock is held, which meant the seats we saw being made would be installed in a bus two days later.

At this stage of the build process the body frame is complete

New Prototype and Testing Centre

Erected within the existing plant, the new Prototype and Testing Centre took 18 months to complete and aims to optimise development planning and the time in which new models can be brought to market. It answers a need for greater capacity in this department, doubling the previous workshop size to 4,100sqm. It has 12 workstation bays, each with overhead gantry equipment for roof top working and can cope with vehicles up to 18m long. In addition to all manner of testing facilities to evaluate economy, instrumentation, noise, vibration and on-road behaviour, features include a thermal chamber that can reach temperatures of 50 degrees C, virtual and mixed reality equipment and a 3D printing machine that can produce plastic parts up to 1.5m long. This is in addition to machining and woodworking capabilities. Over 50 people are employed of which 20 are engineers and training has been increased by 25% this year. Iveco’s other testing facilities are fully linked in with the site.

David Kříž, Managing Director of Iveco Czech Republic, said: “This new Prototype & Testing Centre in Vysoké Mýto is of strategic importance for the development of future vehicle models equipped with the latest technologies, regardless of the propulsion energy.”

Company and product history

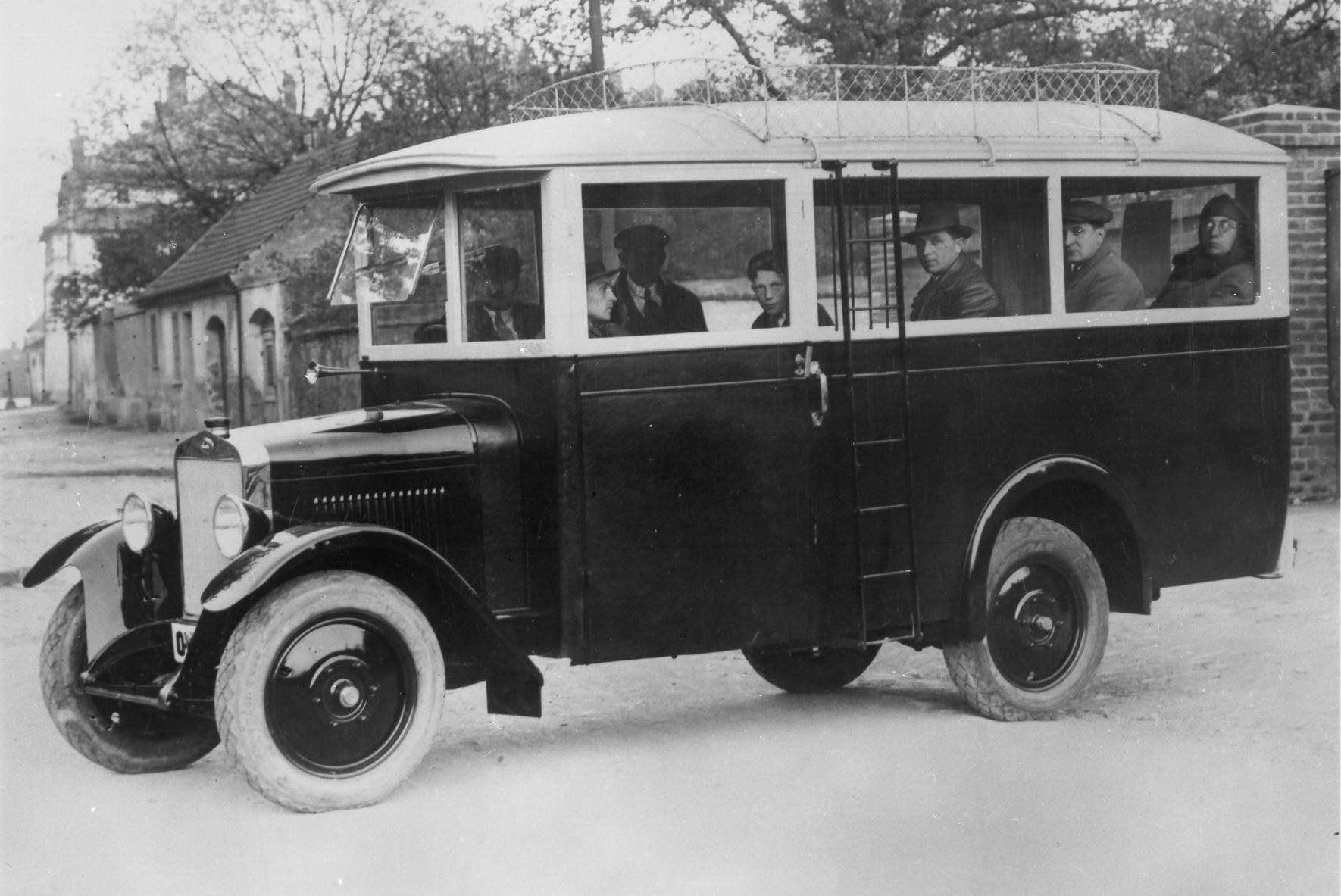

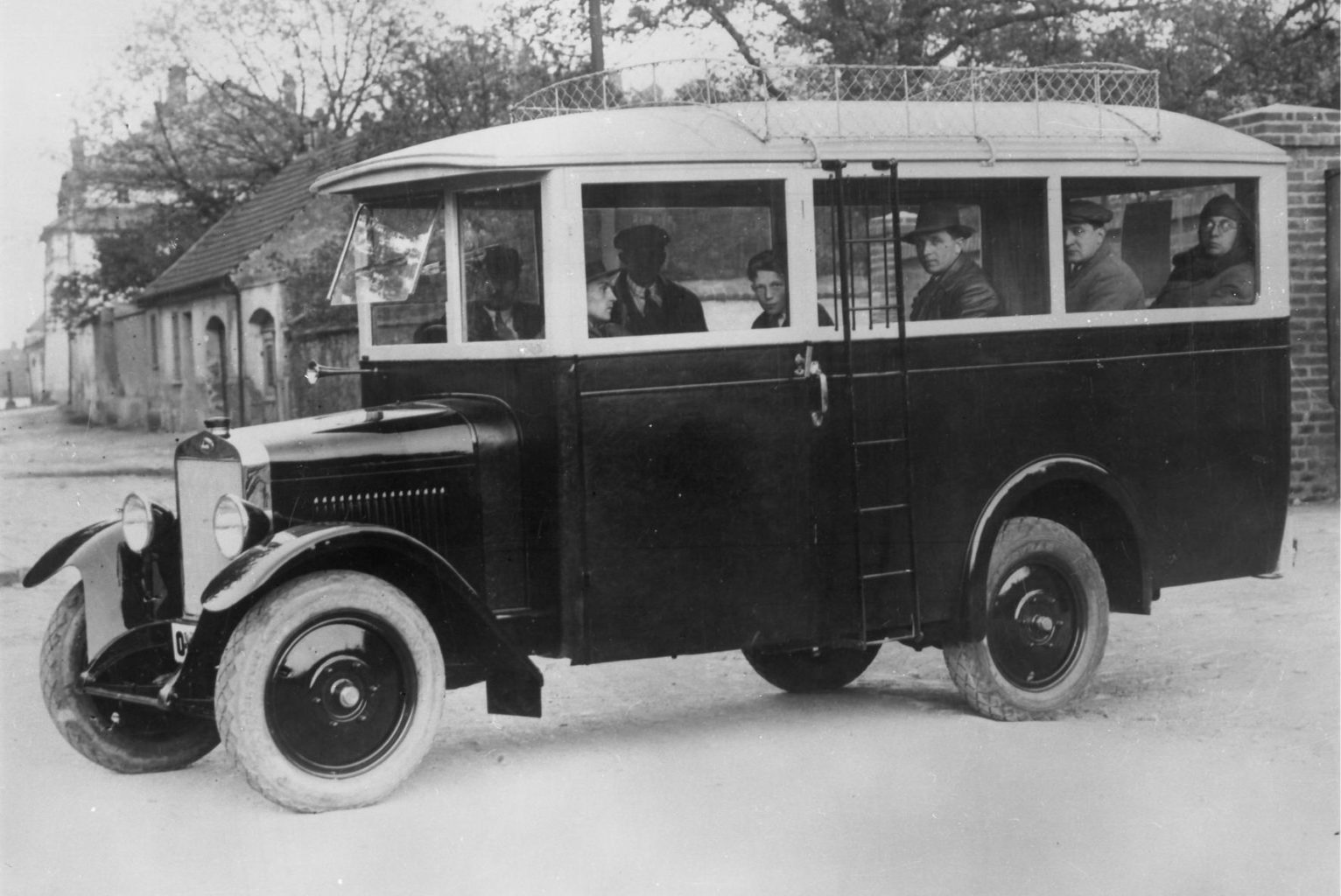

The company’s history began in 1895 when Joseph Sodomka opened a small coachbuilding business producing horse drawn carriages. This developed under his talented son, Joseph Sodomka Junior who in 1928 built the company’s first bus body. Production of buses and car bodies continued until WWII. That the Vysoké Mýto plant survived to become Iveco’s biggest bus building facility is remarkable given the obstacles to the plant’s survival that were overcome over the years. In the war it was supposed to be part of the Panzer tank building network, which would have made it a target for Allied bombers, but the management convinced the occupying powers that they would be better employed building ambulances, small trucks and buses. The first post-war bus offered was the Skoda-based 706RO in 1947 which was to remain in production until 1956. Following the Russian takeover of the country in 1948, the business was renamed Karosa. In 1955, under Soviet influence, it was decided that Ikarus would build all the Bloc’s buses in Hungary, but financed by the local labour unions, a prototype luxury coach was built and it was so good that it convinced the authorities to let them build it. This developed into the 706RTO designed on a Skoda chassis, which was presented at the Brno trade fair in 1956 and entered full production in 1958. Over 27,000 were built at Vysoké Mýto, of which 10,000 were city buses, 15,000 were intercity buses and 2,000 were coaches. The Polish Government bought a licence to build it and formed the Jelcz 41 company which, in 1972, bought the production line and continued building it until 1986.

Joseph Sodomka Junior’s very first bus product was built in 1928

As part of the celebrations, three historic Karosa vehicles were borrowed, one from the local museum and two from a private collector, and displayed at the plant. These were a 706RO bus, a 706RTO coach and an SL11 coach. The SL11 was part of the revolutionary new S family of vehicles launched in 1967, being of integral construction with pneumatic suspension, with an extended front to accommodate a front door, a shorter wheelbase and the 210hp engine mounted between the axles. It was only 3m high because many rail bridges in Czechoslovakia, as it then was, were only 3.2m high. 27,000 were built and it formed the basis for the later 700 and 900 series products of which 37,164 and 12,944 were built respectively. The 900 series launch coincided with Renault’s acquisition of a strategic stake in the company in 1995 and in turn it became part of Irisbus Holdings in 1999. Ongoing investment saw the installation of the first cathodic dip plant for buses in Eastern Europe which revolutionised corrosion protection. A new Bus Design Centre was opened in 2015.

There was a major factory upgrade in 1970. The SM and SL models are seen in build

Crossway

Production at Vysoké Mýto today is primarily about the Crossway, Iveco’s most successful bus and coach product, which dominates the European Class 2 sector taking over half of it. Since it was launched in 2006 over 65,000 units have been produced in a wide variety of forms including a tri-axle 14.5m option and a 10.8m bus in addition to the main 12m and 13m two-axle models. The initial high-floor version was followed two years later by the low-entry LE model. It can be supplied as a diesel, Hi-SCR diesel or XTL/HVO diesel using the Cursor 9 engine or with a variety of alternative propulsion systems including hybrid and CNG or even CNG hybrid. Two years ago, production started of the battery electric version of the LE and the first high-floor electric models are about to be delivered. Though the future is expected to be dominated by electrics, the current position is that 70% of production is diesel, 25% is CNG or CNG Hybrid and only 5% is electric. 90% of production is exported, with the top markets being France, Italy and Spain. At present, the Evadys can only be supplied as a diesel.

Present was the first production Crossway Elec which is one of two with four battery packs destined for a French customer, Autocars Pays de Savoie

A Crossway Elec was available for inspection at the launch. One of two for a French customer, Autocars Pays de Savoie, it featured optional overhead racks and the four-battery pack option with two packs at the rear and two in a tray within the roof that reduces excess headroom in the forward part of the saloon. Between three and six battery packs can be specified but an advantage of only going for the four-battery option is that it leaves the underfloor lockers in place, as this is where they are mounted in five or six battery pack options. Each of the FPT produced Lithium Ion NMC high energy density battery packs provides 69kW. Electricity from the batteries powers a 290kW Siemens Elfa III central electric motor with peak torque of 3,000Nm. This drives through a standard rear axle that is the same as on diesel models. Maximum range is up to 500km. As with the diesel models, the maximum seating capacity is 57 in the 12m model and 63 in the 13m.

The 1,200mm centre door can be fitted with equal size or asymmetric centre doors, the latter in conjunction with a tip-up double seat over the right side of the entrance. Lift options are available with a lift-out floor section in the floor opposite the doorway to accommodate wheelchairs. The bus shown had a Thermo King air conditioning system but a Konvekta heat pump is soon to be offered as an alternative.

This roof section is for an electric bus. The tray holds two battery packs and helps lower the centre of gravity

We were given the chance to don headsets and experience ‘Mixed Reality’ on the prototype Crossway Elec LD. Using this equipment you can walk around and see where you are going, even see to take notes, but at the same time you see the systems illuminated virtually onboard the bus, where they are located and in which direction power is flowing between the various components. It’s all very colourful, if a little disorienting, but gives you a real insight into how the vehicle works.

Crossway has never been offered in right hand drive and I understand that there are no plans to start doing so. Currently, IvecoBus only offers the Daily small bus range in the UK.

Last word

The latest investment underlines the importance to Iveco Bus of the Vysoké Mýto plant as well as its determination to retain its position in the market in a time of great upheaval. Since the first bus was built by the Sodomka family in 1927 approximately 165,000 buses have been completed there. At current rates of production, it will only take seven years to achieve the 200,000 mark.